Fouling is a major problem in industrial operations, especially in distillation columns. Fouling leads to a reduction in efficiency, lower product quality, and, in some cases, even equipment damage. It occurs when unwanted substances accumulate on the surfaces of heat transfer equipment or process vessels, leading to obstruction and reduced fluid flow.

However, Bubble Cap Tray Distillation Column remains an excellent defense mechanism against fouling. This technology provides reliable, efficient, and long-lasting distillation performance, ensuring optimal product quality and yield.

Bubble Cap Tray Distillation Column – A Powerful Distillation Technology

Bubble Cap Tray Distillation Column technology has been used in the distillation process for many years. It still remains one of the most common and effective ways to separate different chemical components from a complex mixture.

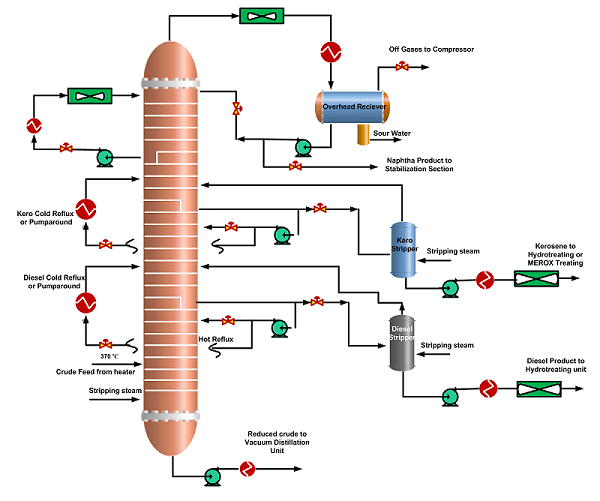

The technology is relatively simple, yet incredibly powerful. The column consists of a vertical tower filled with trays designed to interact with the vapor and liquid mixture. It is equipped with bubble caps that allow vapor to rise through the liquid while ensuring that liquid and vapor pass through each tray efficiently.

Bubbles are generated by steam or air injected into each tray, which helps promote turbulence and contact between the components, resulting in separation of the mixture.

Fouling – A Major Problem in Industrial Processes

Fouling limits the efficiency of distillation columns and can cause significant downtime, maintenance costs, and loss of production during cleaning. Fouling can be caused by several mechanisms, such as deposition of solids, chemical reactions, corrosion, and physical adhesion.

The challenge of fouling has been a significant concern in industrial processes such as distillation, heat exchangers, and reactors. However, Bubble Cap Tray Distillation Column remains an effective tool in tackling fouling.

Bubble Cap Tray Distillation Column – An Effective Defense Against Fouling

Bubble Cap Tray Distillation Column is designed to prevent fouling, one of the critical challenges that detract from the column's performance. It serves as a reliable defense mechanism against fouling by ensuring an even distribution of liquid and vapor and maintaining efficient contact between the mixture components.

Additionally, Bubble Cap Tray Distillation Column operates at low vapor velocities, preventing the build-up of deposits that can promote fouling, making it an effective tool in combating fouling even in harsh operating environments.

Moreover, the distillation trays can be easily removed and cleaned, making maintenance simple and cost-effective.

Shandong Jinta Machinery Group Co. Ltd – The Provider of Quality Distillation Columns

Shandong Jinta Machinery Group Co., Ltd., a leading manufacturer in China, provides quality Bubble Cap Tray Distillation Columns that serve the needs of the chemical and pharmaceutical industries.

With a commitment to innovation, efficiency, and quality, Shandong Jinta Machinery has developed a wide range of ASME-certified distillation columns, based on the Bubble Cap Tray Distillation Column technology, which meets the specific needs of different customers.

Their product portfolio includes rotary dryers, spiral heat exchangers, stainless steel storage tanks, and other innovative products.

Conclusion

Bubble Cap Tray Distillation Column technology remains one of the most effective and reliable ways for distillation, providing optimal efficiency and product quality while combating fouling. Additionally, distillation columns provided by Shandong Jinta Machinery Group Co., Ltd., a leading manufacturer in China, provide a reliable and innovative solution to the challenges of industrial operations. They are committed to offering quality distillation columns and other products that cater to the unique needs of their customers.